Comparison of 316 304 316L 304L Stainless Steel

Comparison of 316 304 316L 304L Stainless Steel.

Comparison of 316/304 / 316L / 304L Stainless Steel.

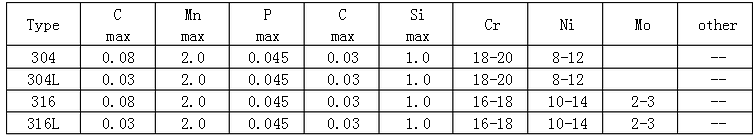

1. Chemical composition

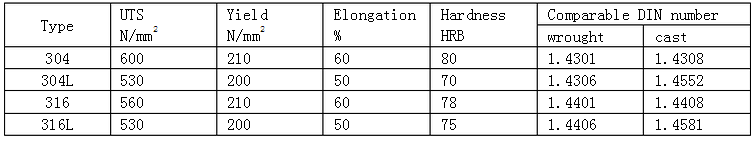

In all steels, austenitic stainless steels have the lowest yield point. Therefore, from the mechanical properties, austenitic stainless steel is not used in the best stem material, because to ensure a certain strength, stem diameter will increase. The yield point can not be improved by heat treatment, but can be improved by cold forming.

2. Mechanical properties

3. Resistance to chemical corrosion

In general, 304 stainless steel and 316 stainless steel in the chemical resistance of the difference is not, but in some specific media under the difference.

Initially developed for the 304 stainless steel, under certain circumstances, this material on the point of corrosion (Pitting Corrosion) is more sensitive. An additional 2-3% molybdenum can reduce this sensitivity, so the birth of the 316. In addition, these additional molybdenum can also reduce the corrosion of certain hot organic acids.

316 stainless steel food and beverage industry has become almost standard material. Because of the worldwide shortage of molybdenum and 316 stainless steel in the nickel content more, 316 stainless steel prices are more expensive than 304 stainless steel.

Pitting corrosion is a phenomenon mainly caused by the deposition of stainless steel surface corrosion, which is due to lack of oxygen and can not form a protective layer of chromium oxide. Especially in small valves, the possibility of deposition on the valve plate is very small, so pitting corrosion rarely occurs. In all types of water medium (distilled water, drinking water, river water, boiler water, sea water, etc.), 304 stainless steel and 316 stainless steel corrosion resistance is almost the same, unless the medium chloride ion content is very high, then 316 stainless steel more suitable.

In most cases, 304 stainless steel and 316 stainless steel corrosion resistance is not much different, but in some cases may also vary widely, the need for specific analysis of specific circumstances. Generally speaking, the valve users should be aware of because they will be based on the media to select the container and pipe material, we do not recommend to the user recommended materials.

4. Low carbon type stainless steel

The corrosion resistance of austenitic stainless steel comes from the chromium oxide coating formed on the metal surface. If the material is heated to 450 ℃ to 900 ℃ high temperature, the structure of the material will change, along the crystal edge of the formation of chromium carbide. As a result, the chromium oxide protective layer can not be formed at the crystal edge, resulting in a reduction in the corrosion resistance. This corrosion is called "intergranular corrosion".

Which developed 304L stainless steel and 316L stainless steel to combat this corrosion. 304L stainless steel and 316L stainless steel carbon content is low, because the carbon content is reduced, so it will not produce chromium carbide, it will not produce intergranular corrosion.

It should be noted that a high susceptibility to intergranular corrosion does not imply that non-low carbon materials are more susceptible to corrosion. In the high-chlorine environment, this sensitivity is also higher.

Please note that this phenomenon is due to high temperature (450 ℃ -900 ℃). Welding is usually the direct cause of this temperature. For the soft seat conventional butterfly valve, the use of low carbon stainless steel does not make much sense since we do not weld on the valve plate, but most specifications will require 304L stainless steel or 316L stainless steel.

5. Magnetic

Because of the extensive use of austenitic stainless steel, to the people caused by all the stainless steel is not the wrong impression of magnetic. For austenitic stainless steel, the basic can be understood as non-magnetic, quenched forged steel is indeed the case. But the 304 formed by the cold forming process is somewhat magnetic. For cast steels, 100% austenitic stainless steels are not magnetic.